It is awe-inspiring to walk into today’s manufacturers and see the efficient and productive way things are made. Yet, even though the United States remains one of the most productive countries, manufacturing productivity has remained flat over the past decade. This should be a major concern. Productivity is a vital foundation for stronger companies, rising standards of living, and vibrant communities.

Industry 4.0 Can Solve the Productivity Gap: Five Actions for Leaders of Small and Mid-sized Manufacturers

Posted by David Boulay on Jan 28, 2020 8:30:00 AM

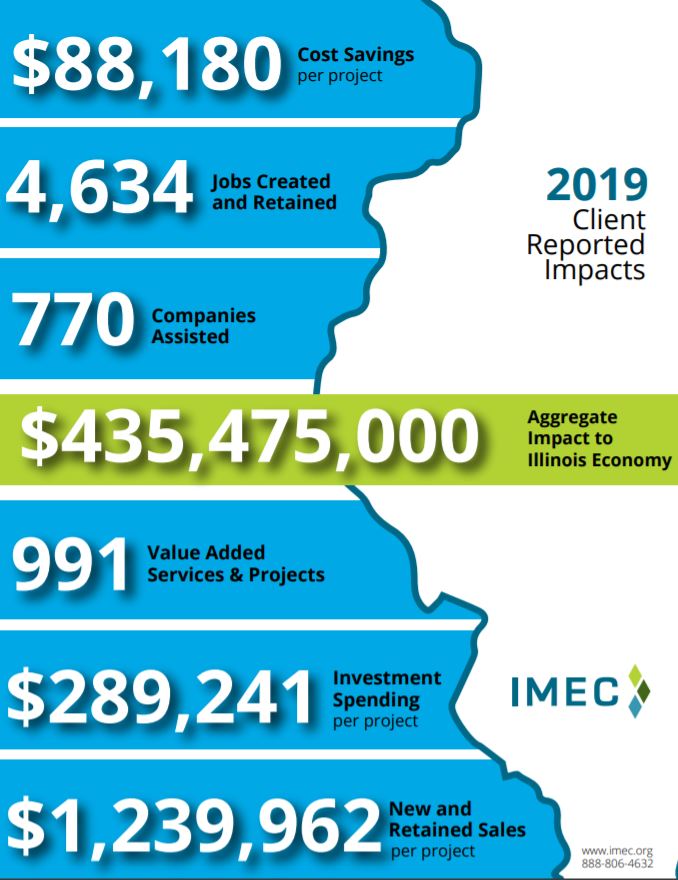

770 Companies Report Impacts that are Improving Illinois Manufacturing

Posted by Simone Erskine on Jan 17, 2020 9:47:38 AM

As the cliché, but true saying goes: “numbers don’t lie.” We can’t help but agree as we review our 2019 client reported impacts! While it is certainly a time of celebration here at IMEC, it’s also a celebration for the 770 manufacturers who have invested in their competitive futures. By partnering with IMEC and reporting the impacts our work has contributed to their business, it allows us to show that we all play an important role in a much bigger story. These numbers speak volumes to the value our clients add to our manufacturing ecosystem. Not only are companies on a path to enterprise excellence, but they are also strengthening Illinois’ economic well-being, their communities, and their organization as whole.

2020 Conference on Enterprise Excellence: Learning from High-Performing Organizations Across Industries

Posted by Simone Erskine on Jan 6, 2020 2:36:21 PM

Every year, IMEC hosts the Conference on Enterprise Excellence. During this one day of incredible learning, manufacturers, healthcare professionals, educators, and business leaders come together to share best practices in performance excellence that can be applied to any operation.

You may be wondering: “what can a manufacturer learn from a hospital or a school?” Well, a lot. Every organization has similar areas of focus – leadership, workforce, strategy, operations, customers, measurement and results, and technology implementation. Ensuring that these areas are held to high standards will result in a high performing organization. The 2020 conference features business leaders who have transformed their organizations into reputable, high performing ones by implementing trusted and effective strategies that are replicable for any industry.

The Bus Factor - Talent and Succession Planning to Build Your Leadership Pipeline

Posted by IMEC on Oct 8, 2019 10:19:09 AM

When I was leading Organizational Development strategies at my former company, we used to call it the “getting hit by a bus” scenario. Then someone decided that was too morbid so it was rephrased to the “winning the lottery” scenario. In either case, we used the scenario to help the C suite and other senior leaders to think through who would replace their most critical employees if they no longer worked at the company. If your best and brightest employee won the lottery one evening and didn’t show up for work the next day, how would operations continue with minimal disruption to employees, customers, and stakeholders?

LMI Chicago: Taking Leaders to the Next Level

Posted by Simone Erskine on Oct 3, 2019 12:12:43 PM

Who is LMI Chicago?

LMI Chicago is part of a worldwide organization called Leadership Management International. For over 50 years, in 80 countries and 27 languages, LMI programs have helped develop effective and productive leaders. Jeff Johnson, President of LMI Chicago, personally completed the LMI programs with his management team (at his previous company) prior to starting LMIChicago four years ago. Witnessing the benefits, Johnson was attracted to the proven programs and processes and the difference they made in people’s lives.

In Case you Missed it - Cobots: Solving the Manufacturing Labor Challenge

Posted by Emily Lee on Aug 29, 2019 2:49:35 PM

IMEC partnered with Fusion to host the Cobots: Solving the Manufacturing Labor Challenge event. The fun and informative afternoon featured educational sessions led by cobot vendors and experts, all in the name of helping manufacturers understand the benefits of implementing cobots at their facility: improved productivity, safer working environment, and more efficient installation than traditional automation.

Not Yet Using the Baldrige Excellence Framework? Five Ways Forward

Posted by Simone Erskine on Jul 19, 2019 9:36:01 AM

This is an original article from NIST's Blogrige, the official Baldrige Blog, written by Christine Schaffer.

The national Baldrige Performance Excellence Program's website is the source of the regularly updated, widely validated leadership-and-management-strengthening tool known as the Baldrige Excellence Framework (which includes the Criteria for Performance Excellence).

Are you already using this comprehensive self-assessment guide to strengthen your organization’s performance?

If not, would you like to benefit from improvements and innovation in your approaches to leadership, strategy, customers, knowledge management and performance measurement, workforce, operations—and get better results in all these areas?

What Can Cobots Do for Your Business?

Posted by Simone Erskine on Jun 27, 2019 12:19:42 PM

This is an original infographic from NIST Manufacturing Innovation Blog.

Manufacturing industries as varied as automotive, electronics, chemical products and food already use collaborative robots (cobots) for tasks such as assembly, loading and packaging. The partnership between humans and cobots is an important one that combines tasks and drills with thoughts and skills.

MEP National Network: Cobots Level the Playing Field

Posted by Simone Erskine on May 28, 2019 10:29:47 AM

This is an original article, written by Buckley Brinkman, the Executive Director/CEO of the Wisconsin Center for Manufacturing and Productivity (WCMP).

Reluctance to Employ Cobots Driven by 4 Common Misconceptions

It has been nearly six decades since the first industrial robots rolled on to a General Motors assembly line in Trenton, New Jersey. Today, a new generation of collaborative robots is changing how the manufacturing sector operates. These semi-intelligent machines are driving growth and improving efficiency not only for the GMs of the world, but also for small and medium-sized manufacturers (SMMs) as well.

Transforming the Workforce in the Era of AI Expansion - A MAPI Foundation Research

Posted by Simone Erskine on May 21, 2019 3:10:00 PM

The following is a description of MAPI Foundation's research on how AI is transforming the workforce, written by MAPI Foundation.

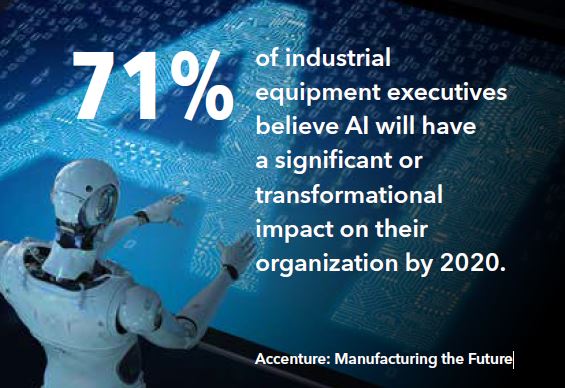

Manufacturing leaders are seeking strategies and solutions to address a burning question:

How will AI transform the workforce – the people, roles, skillsets – in the next 5 years?

THE CHALLENGE

Predictive maintenance, human-robot collaboration, and generative design are a few of the applications of artificial intelligence remaking manufacturing. Expectations continue to rise for AI to unlock elusive productivity gains. Industry leaders are adapting to the technological change — AI and related Industry 4.0 and IIoT technologies — that will continue to reshape their workforce, either through the automation and replacement of some workers or upskilling and new roles of others.