The IMEC Advanced Manufacturing Technologies Services (AMTS) service is the strategic incorporation of nine (9) core Industry 4.0 technologies along with all the enterprise’s other continuous improvement initiatives. Looking at AMTS, we see the confluence of several process mapping tools come to bear, ensuring that the enterprise has a unified, well-coordinated and well-integrated improvement system for achieving their strategic and operational goals / targets.

A Practical Guide to Value Stream Mapping - Part 5, with Full E-Book

Posted by Greg Thompson on May 3, 2019 8:57:14 AM

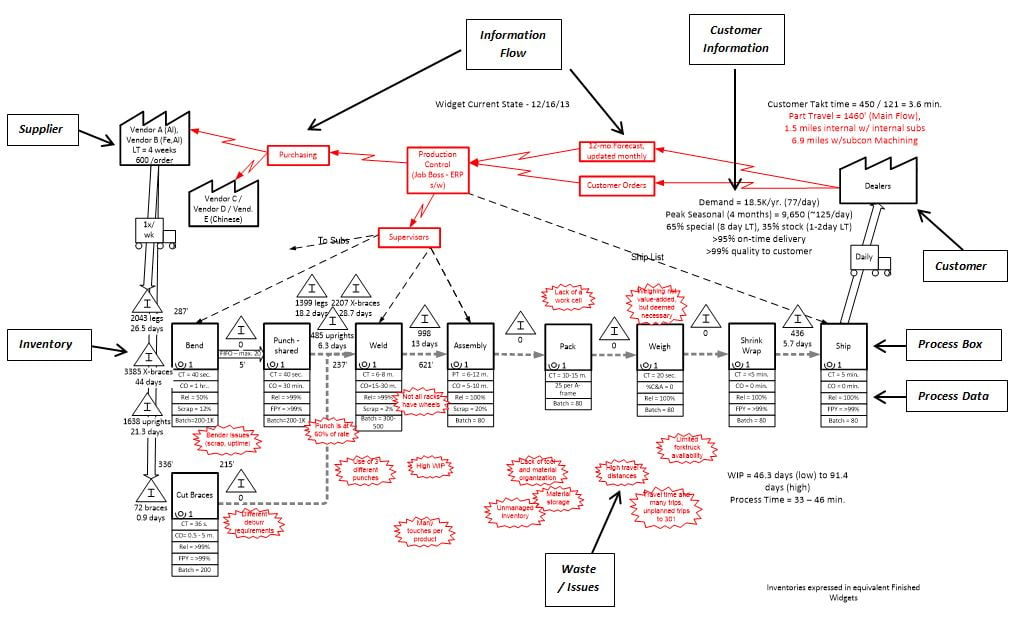

Current State vs. Future State VSM

Current State is intended to represent conditions that are present today. Not ideal conditions or how it is supposed to be, but as close to reality as possible. Future State should be your goal, your blueprint, your roadmap; this is your destination. It should be optimistic, but not unrealistic. We generally plan for a timeframe of 6 – 12 months to get to Future State. There are times an interim map is drawn, which I often call “Current State with kaizens.” Kaizen is the Japanese translation for ‘good change’. The interim map with the kaizens can be a bit messy, but it helps represent the transition from Current State to Future State. There are times when the Future State isn’t structurally different than the Current State, and the Future State is the Current State with kaizens.

A Practical Guide to Value Stream Mapping - Part 4 of 5

Posted by Greg Thompson on May 2, 2019 8:22:00 AM

Can I facilitate the VSM myself, or should I use an outside resource?

Short answer: Sure. You probably can facilitate it yourself; and should if you’re comfortable with it. VSM isn’t rocket science. But, depending on your level of experience with lean / VSM and company dynamics, there may be advantages to using an outside resource.

A Practical Guide to Value Stream Mapping - Part 3 of 5

Posted by Greg Thompson on May 1, 2019 8:06:00 AM

Suppliers and Customers

Most Value Stream Maps have multiple suppliers and customers. Some have several hundred. You generally can’t put them all on a map, so you want to focus on the most important few.

I once worked with an aerospace supplier who could count their customers on one hand; in this case they were included individually on the VSM. Sometimes the scope is such that we have a single, internal customer. Other times, we have many customers which can be represented as a generic “Customers” or perhaps we consider the Warehouse or Distributors to be the customer…or a combination of these.

A Practical Guide to Value Stream Mapping - Part 2 of 5

Posted by Greg Thompson on Apr 30, 2019 8:39:02 AM

Where to start / Granularity

At what level should we map? I’ve done VSMs where an entire factory (a big one, making lawn tractors) was merely a box on the map. Our focus was on logistics and distribution- we included inventory, capacity, and setup time in the factory box, but that was about it. On the other end of the spectrum, I’ve done VSMs for an Order Entry process. We got into much greater detail and discussed when/how credit approvals were done, etc. The level you go to really depends on your goals and scope of the VSM. If I were taking a first crack at VSM, I’d start door-to-door in a process, using major activities as my process boxes. If you find that one or more of these process boxes are real issues or need a better depth of understanding, you can complete a follow-up VSM on that process which includes more detail.

A Practical Guide to Value Stream Mapping - Part 1 of 5

Posted by Greg Thompson on Apr 29, 2019 11:21:00 AM

I don’t claim to know everything about Value Stream Mapping (VSM). However, I have used VSM extensively over the past 15 years in many different industries and situations. I believe strongly in the value of the tool and want to share some of my experience with the intention of helping novice Continuous Improvement leaders head in the right direction with VSM.

Are your Accounting Practices Value-Added?

Posted by Amy Fitzgerald on Aug 23, 2016 12:00:31 PM

Written by Andy Cave, IMEC Regional Manager

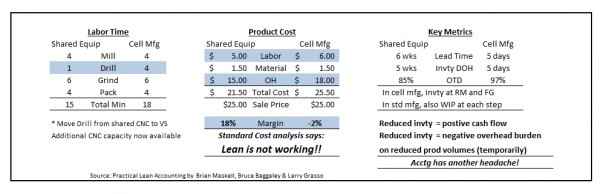

An example of how an accounting approach may hinder continuous improvement efforts

The Accounting concept of Standard Costing was developed in the 1920’s, and its application has remained fairly constant. Manufacturing was noted for minimal product variation (“You can buy a Model T in any color, as long as it’s black”) and long production runs creating lots of inventory whose financial value had to be estimated. Lean principles have changed the manufacturing world significantly, with shorter set-up times and significantly less inventory. Meanwhile, Accounting still spends time analyzing and understanding labor, material and overhead variances; often generating thousands of related transactions and accrual entries. In the Lean world, these are Non Value-Added activities; the customer is not willing to pay more for our cost variance analysis excellence.