Some Hard Truths.

Cybersecurity and Industry 4.0 – What You Need to Know

Posted by IMEC on May 17, 2022 3:26:50 PM

This is an original article from the NIST Manufacturing Innovation Blog.

This blog is part one of a series on cybersecurity and Industry 4.0.

This morning my favorite local morning news program had an interesting segment on new slang words and what they mean. While the definitions were probably not necessary for Millennials or Generation Z, for Baby Boomers like me it was an eye-opening vocabulary lesson. I must admit I didn’t know what boujee meant, even though I had heard it a few times – like when my niece said the wine glasses I used at Thanksgiving were boujee.

Technology Selection: The Latest Updates

Posted by Ken Wunderlich on Apr 26, 2022 10:20:14 AM

There are literally thousands of options that you can pursue in manufacturing, with the potential return on investment varying from a -100% return to a 100%+ return. The challenge for manufacturing companies is to have a process to determine what the next steps should be. IMEC has a basic process that can help you to navigate these waters and bring some clarity to your next step.

10 Important Insights About Advanced Manufacturing Technology Adoption in Illinois

Posted by IMEC on Nov 30, 2021 3:23:40 PM

In the spring of 2021, IMEC, Illinois Manufacturers Association (IMA), Technology & Manufacturing Association (TMA), and Valley Industrial Association (VIA) partnered with the W.E. Upjohn Institute for Employment Research to survey manufacturers about their adoption of Advanced Manufacturing Technologies and processes, achieving a phenomenal 87% response rate.

Two Industry 4.0 Technologies Primed for the Food Manufacturing Industry

Posted by IMEC on Nov 12, 2021 12:51:15 PM

Written by Matthew Inniger of Manager of the Advanced Technology Program of CIFT, part of Ohio MEP. This article first appeared on the NIST Manufacturing Innovation Blog.

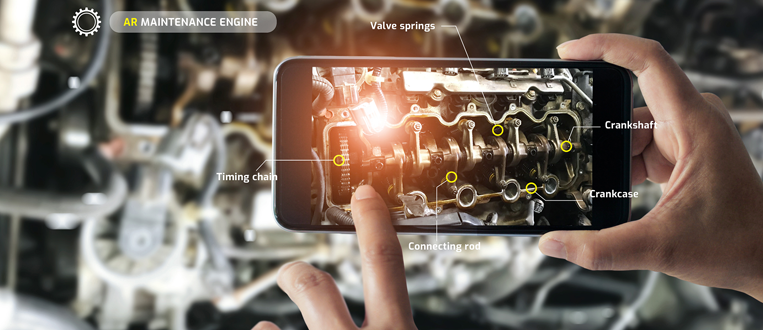

This is an exciting time in the food manufacturing industry. The innovations and technology associated with Industry 4.0 are making it easier for small and medium-sized manufacturers to overcome obstacles in ways that at one point would not have been considered. While manufacturers have previously been slower to move toward incorporating advanced industry technologies due to the high level of regulation and biologically complex products with which they work, innovation is becoming more widely accepted as a key to industry sustainability. Two examples of such Industry 4.0 technologies are automation and augmented reality.

Culture is the key to productivity

Posted by IMEC on Sep 17, 2021 4:39:03 PM

Even in the 21st century when automation and digital disruption are all the rage, manufacturing productivity is still a people business. It’s not just about software, management theories, or even logic — people are a hybrid of reason and emotion and managing to optimize productivity and other metrics is as much about how people feel, as it is about what and how they think.

Hiring Tech-minded Millennials: Are you on board?

Posted by IMEC on Sep 14, 2021 3:35:18 PM

How important is it to bring Millennials into your workforce? Let’s put it this way: Like an unstoppable speeding train, the future is coming up fast. Couple that with the fact that the future belongs to those who adapt advanced manufacturing technologies. Will yours be the company running to catch the train after it has left the station?

Manufacturing Execution Systems: What You Don’t Know Can Hurt You

Posted by IMEC on Jun 17, 2021 1:07:58 PM

This article is written by Chuck Werner, Manager of Operational Excellence at Michigan Manufacturing Technology Center - part of the MEP National Network, and originally published in IndustryWeek.

Smart Manufacturing is the manufacturing of the future, and, at its core, works to save time, money, and resources. One valuable tool in the move toward Smart or Smart(er) Manufacturing is the implementation of a manufacturing execution system. A Manufacturing Execution System (MES) is an automated system that utilizes real-time data to assist you in measuring how your production equates with financial performance.

4 applications you should produce with additive manufacturing

Posted by IMEC on May 28, 2021 1:40:49 PM

This is an original article from Fast Radius.

When people think of additive manufacturing (AM), the first thing that often comes to mind is prototyping. When you need to iterate on a design quickly without the constraints of traditional manufacturing runs, AM works well because there’s no hard tooling involved, making rapid iteration possible.

Five Simple Digital Applications That Are Changing Manufacturing

Posted by IMEC on Dec 22, 2020 10:19:18 AM

Written by Michael Taylor, Mechanical engineer and project manager at NIST MEP.