Written by Roger Shrum, IMEC Regional Manager

In my work with manufacturers, I’ll encounter leaders who are frustrated with the slow pace of implementation of their continuous improvement programs. They are concerned that they are not seeing the payback they were hoping for. What I share with them is sometimes unsettling: Many enterprise-wide lean deployment programs become stalled because the top manager in the company has not clearly articulated his/her personal vision and committed to making it successful.

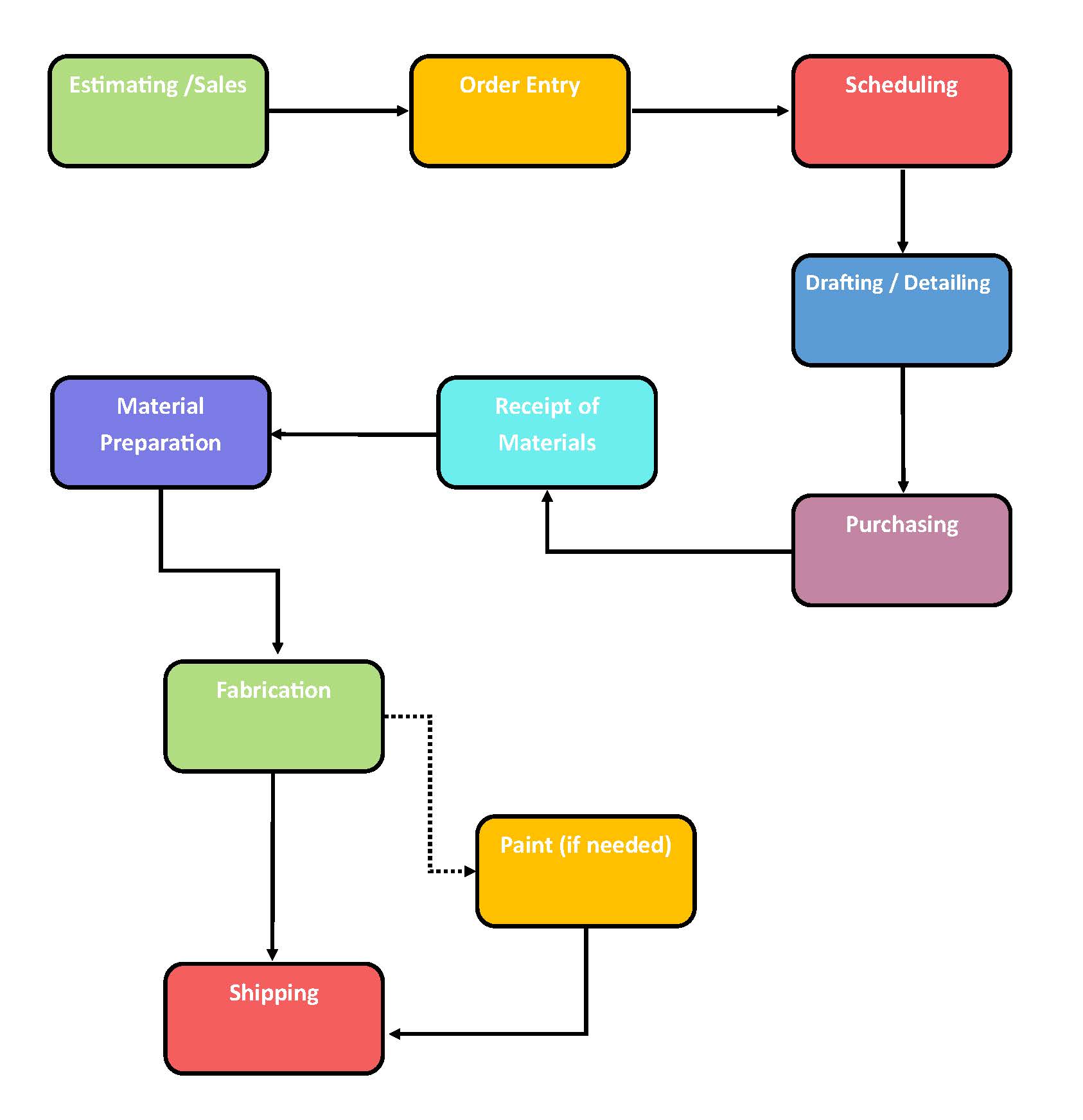

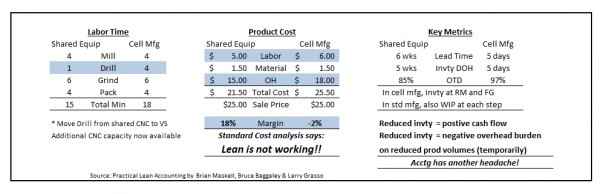

In one example, a company I was advising faced chronic late delivery problems, which jeopardized its reputation with longstanding customers and opened the door for its competitors to take business away. The company was forced to work significant overtime and expedite production just to stay in the game. This company had a history of waiting for a downturn in business to shore up its delivery performance. Along the way, they “dabbled” in implementing lean methods, but as orders increased, a full lean implementation was shelved. In retrospect, these well-meaning, busy leaders now realize that they may have missed an opportunity for significant growth by not positioning the company to adequately meet customer needs during the upside of the cycle.