During these unprecedented times, one group stood out for their contributions to society. Those at the frontlines! Nurses, doctors, grocery store clerks, and manufacturing associates. “Production” associates, as this recent article points out, deserve our appreciation for providing us with the goods and services we need. Arguably risking themselves in the process!

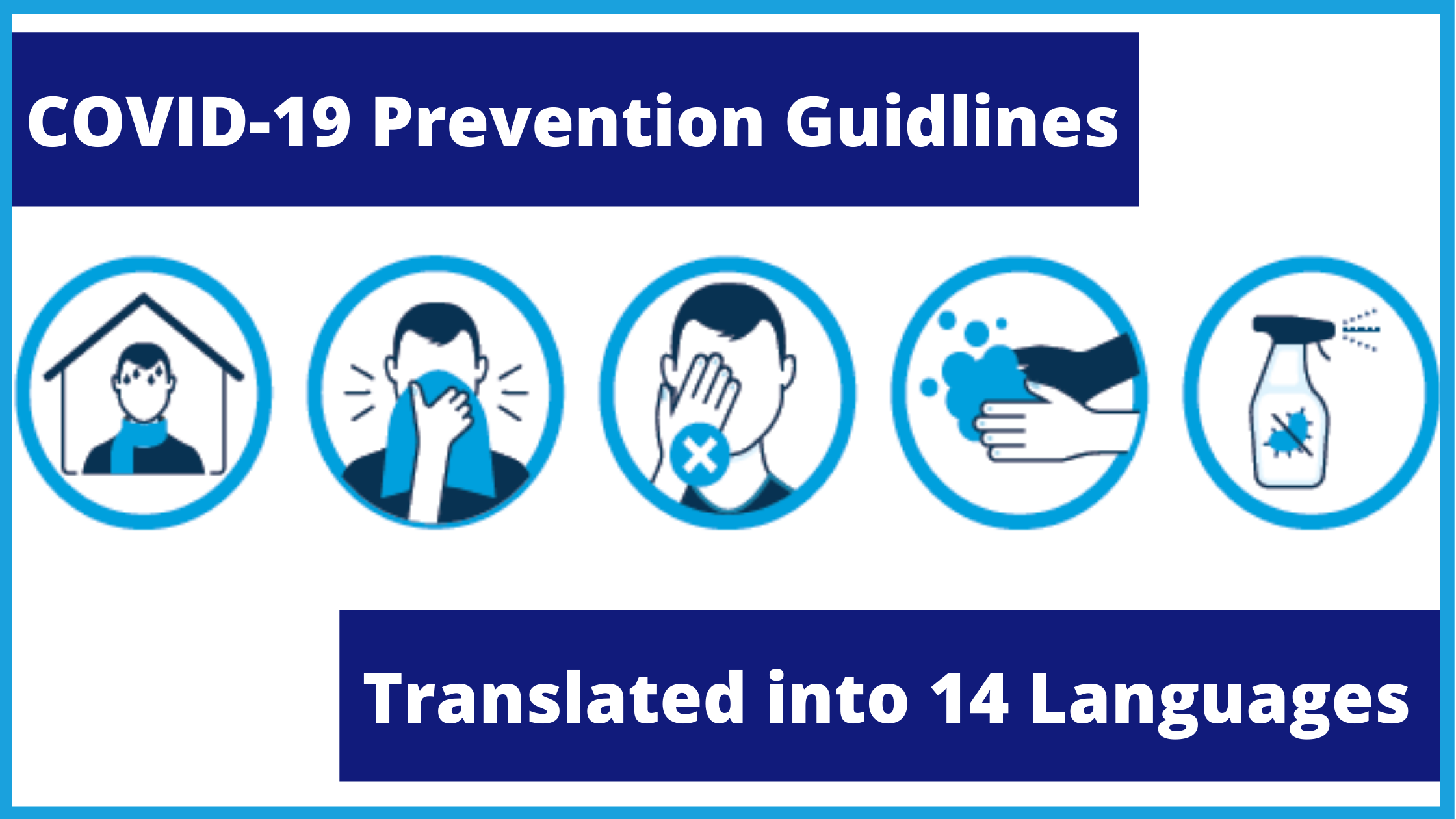

COVID-19 Prevention Guidelines in 14 Languages

Posted by IMEC on Jun 30, 2020 12:05:46 PM

The CDC has defined general guidelines that will help prevent the spread of COVID-19. To help share these with a larger audience, our friends at Argo Translation created an infographic that demonstrates the guidelines in 14 languages:

Strengthening your Quality System Post COVID-19

Posted by Jesse Brady on Jun 26, 2020 2:19:29 PM

As Illinois manufacturers settle back into a “new normal” there is no shortage of responsibilities weighing on our minds. One area that can easily get overlooked as we move through this uncertain time is your Quality Management Systems (QMS). With our focus elsewhere, new procedures or training can get implemented without proper documentation. We can get behind on our internal auditing schedule. Or we lose sight of action items from prior meetings and audits.

Restarting Your Facility

Posted by IMEC on Jun 25, 2020 3:44:17 PM

Written by Larry Bouvier, Vice President of Fuss & O'Neill Manufacturing Solutions.

As businesses and facilities begin to reopen, employee health and safety are paramount. Cleaning, proper distancing, and personal protective equipment have always been important safety precautions, but are now more important than ever. But it is important to remember that while employees are returning to work, facilities’ support equipment itself also needs to be brought back to work in a safe and thoughtful manner. An unused sink drain may weep noxious odors, cooling fans may have burnt out, and security gates might balk at opening easily. The health and safety of your building, and the systems that make it habitable, is important to the health and safety, not to mention comfort, of your employees. Prior to opening a facility, managers need to create checklists and inspect and test all machinery.

Cover Smart. Do Your Part. Slow the Spread

Posted by Mary Hallock on Jun 25, 2020 12:55:15 PM

If you could do one thing to prevent someone from contracting COVID-19, would you? If you could do one thing to help put the economy back on the path to recovery, would you? Well, you can! And, it’s a simple thing to do. Anyone can do it. But a lot of people aren’t.

If it is that easy, why isn’t everyone doing it? Good question. But here is all you have to do – wear a mask. It’s that simple. It doesn’t have to be fancy – a simple cloth face covering can make a big difference.

HVAC Best Practices Post COVID-19

Posted by Jesse Brady on Jun 19, 2020 11:42:13 AM

As businesses open back up everyone’s attention is on keeping their employees & coworkers safe. While CDC guidelines regarding face coverings, frequent hand washing, and disinfecting protocols are the best way to slow the spread of COVID-19, there are other ways for organizations to slow the spread. The ASHRAE (American Society of Heating, Refrigerating and Air-Conditioning Engineers) formed a task force to provide guidelines on how a building’s HVAC systems can help slow the spread.

How to Implement Standard Work in a Covid-19 Environment

Posted by Greg Thompson on Jun 18, 2020 2:12:37 PM

Coauthored by Rick Wrinkler and Greg Thompson.

Standard work means determining and documenting the ideal process to produce correct and consistent results. It represents the best sequence and the most efficient methods to perform a process. It is considered a way to achieve the highest possible degree of consistency in any process. The purpose is to ensure that everything is done by everyone in a similar manner and carry out the work that achieves the highest quality, best service, and lowest cost possible.

In the world of Lean Manufacturing, this definition and adherence to Standard Work has resulted in positive, repeatable results in a variety of industries. In today’s Covid-19 environment, practitioners with years of experience in industry strongly believe that Standard Work will and should be one of the foundational tools to develop, implement, and maintain strategies to combat the Coronavirus in a manufacturing environment.

10 Points of Concern During a Recession

Posted by IMEC on Jun 12, 2020 3:54:31 PM

While it's impossible to pinpoint the timing of an economic pullback or recession, it is possible to take steps to help protect your business during such an event, as well as create ongoing resilience and prepare for the upswing!

The New Supply Chain: Spring Training

Posted by IMEC on Jun 12, 2020 9:50:41 AM

Part 6 of "The New Supply Chain" blog series by Mike Loquercio, Vice President of Supply Chain at Greenleaf Foods.

We are starting to see some signs of the economy opening up and supply chains getting some “swings in the cage” before the full season begins. In many industries, COVID19 demand has stretched the supply chain beyond any reasonable expectations and yet we have found creative ways to make it work. In other industries, we have been operating with diminished needs and looking for ways to repurpose and pivot to support the health care industry.

Leaders: It is Time to Walk the Line - Listening and Responding to your Customers and Employees

Posted by David Boulay on Jun 11, 2020 12:46:08 PM

No, I am not referring to the classic Johnny Cash song that I often heard my father play in my youth. Although perhaps a few lines of the lyrics are fitting.

No doubt the pandemic crisis and social unrest have shaken many of our companies, our work colleagues, and ourselves to the core. We have had our hands full trying to address challenges amid massive uncertainty. A friend and I were recently lamenting how customer service appears to be at an all-time low. We could cite several examples of carefree and lacking customer service. Seemingly, it is OK to explain away poor service and quality “because of COVID”. Understandably, our companies are challenged to perform. As leaders, we have likely taken our eye off the basics while dealing with the onslaught of uncertainty.