While it's impossible to pinpoint the timing of an economic pullback or recession, it is possible to take steps to help protect your business during such an event, as well as create ongoing resilience and prepare for the upswing!

- Solidify Relationships with Your Top Customers

Your customers will feel pressure to reduce costs during a stressful economy, which means they will be more likely to switch suppliers for price concessions. They will also be on high alert for supply chain instability. Establish multiple communication paths and regular communication channels with your top customers. Show them where you add value beyond pricing, such as high quality and on-time delivery.

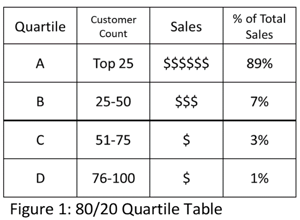

Your 'A' customers are generating the lion share of your revenue and profits. Make sure that you have solid relationships with this group. To identify your top customers, start by listing your customers by annual sales, sorting by highest to lowest. Next, divide the total number of customers by four. The top fourth is your 'A' customers, and the next fourth is your 'B' customers, the next group is 'C's and the final are your 'D' customers. You will likely find numbers similar to those shown in Figure 1.

Your 'A' customers are generating the lion share of your revenue and profits. Make sure that you have solid relationships with this group. To identify your top customers, start by listing your customers by annual sales, sorting by highest to lowest. Next, divide the total number of customers by four. The top fourth is your 'A' customers, and the next fourth is your 'B' customers, the next group is 'C's and the final are your 'D' customers. You will likely find numbers similar to those shown in Figure 1.

- Tighten Up Your Cash Flow

We all know "cash is king," which is especially true in a tough economy when you need to tighten the grip on your cash flows.

- Inventory Management

Ideally, you are turning raw materials into cash in the shortest time possible. However, during a recession, you may have too much inventory stuck in the pipeline. Inventory is cash sitting on a shelf.

- Review All Non-Payroll Spending

Rising costs are a part of the business; cost savings initiatives should also be.

- Set and Stick to a Budget

Many businesses do not spend enough time planning or budgeting. Having an idea of where you are going and an outline of how you will get there is necessary for success. While no one can accurately predict spending down to the line item, you can get close in aggregate.

- Streamline Key Processes

Waste is present in nearly every process, from defects and errors to excess waiting. Apply Lean Thinking to streamline your processes and remove waste and reduce costs.

- Improve the Employee Experience

Look after your team. Finding skilled workers is extremely difficult. During a downturn, we will typically look to reduce the payroll to save money, therefore losing skilled workers.

- Ramp Up Your Marketing Efforts

This sounds a bit counter-intuitive, but it will make sense. In a downturn, sales drop off, and companies pull back on spending for marketing to save money. When these resources are reduced, it is even harder to maintain market presence and locate new revenue sources.

- Protect Your Cash Reserves

Having a cash reserve can be the difference in making it to the other side of a downturn.

- Create Contingency Plans and Risk Management

If you have not prepared a contingency plan, it is never too late!

Much of the advice outlined above is just good business practice. Doing these things will provide excellent business results in good economic times and improve your ability to make it through the bad times. Also, document the lessons learned through the recession to prepare your organization for the future. Finally, be ready for the recovery!

Get the full details on the 10 points in the whitepaper. It includes detailed steps for each point as well as information on how IMEC can help.

Manufacturing the Future: Challenges and Opportunities Webinar

Hear the national perspective on manufacturing, as the industry faces opportunities and challenges as a result of economic uncertainty. We welcome Kenneth Voytek, Chief Economist with the Manufacturing Extension Partnership (MEP) program in the National Institute of Standards and Technology (NIST) to lead this session.

June 17 @ 11:30am