Looking to improve operational performance?

IMEC partners with the International Society of Automation for new resources.

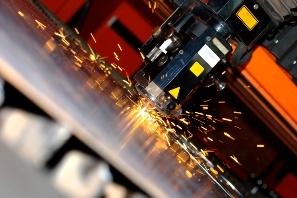

As an official partner of IMEC, the International Society of Automation is committed to helping Illinois' small- and mid-sized manufacturing companies boost revenue, reduce costs, and improve overall operating performance. ISA develops industry-proven automation standards, training, educational resources, and certification programs that produce more capable and competent workforce; safer and more secure and reliable operating environments; and more efficient and profitable results.