-1.jpg?width=345&name=images%20(1)-1.jpg) It has been a little over a year since the beginning of the pandemic. As you are rebounding from the global crisis, thinking back to the past year, what a great challenge that was. Now, as you continue to operate with the pandemic, what is next? What steps are you taking to protect your company? To strengthen and to make sure you stay competitive during this chaotic time? The Cook County Bureau of Economic Development and IMEC wondered the same thing, therefore we reached out to manufacturers seeking answers. Using a 10-questions survey aligning with the US Commerce NIST Baldridge Performance Excellence Framework, over 1000 manufacturers responded with their priorities. In which, over half responded with ‘Creating Growth Opportunities’ as the number one priority.

It has been a little over a year since the beginning of the pandemic. As you are rebounding from the global crisis, thinking back to the past year, what a great challenge that was. Now, as you continue to operate with the pandemic, what is next? What steps are you taking to protect your company? To strengthen and to make sure you stay competitive during this chaotic time? The Cook County Bureau of Economic Development and IMEC wondered the same thing, therefore we reached out to manufacturers seeking answers. Using a 10-questions survey aligning with the US Commerce NIST Baldridge Performance Excellence Framework, over 1000 manufacturers responded with their priorities. In which, over half responded with ‘Creating Growth Opportunities’ as the number one priority.

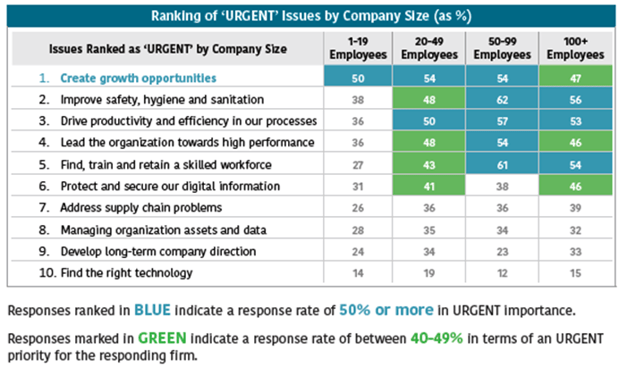

Simply put, if there are no sales, nothing else matters! This is particularly consistent for small firms that have less than 20 employees, which makes up nearly 70% of the respondents, closely mirroring the current national percentage of small manufacturers. Recognizing the presence of COVID-19, many companies were forced to quickly adapt by changing the way of conducting business. Plant layouts were changed to keep up with health and regulations. Face-to-face meetings were reduced as virtual meetings became a need instead of an option. New investments were made and delayed keeping up with the sudden disruption. To our surprises, ‘Find the Right Technology’ has been ranked the least urgent among all the respondents.

This requires further discussion as Manufacturing 4.0 continues to be an important topic among policymakers. The pandemic has brought new opportunities and new risks, such as cybersecurity is now prominent for every manufacturer regardless of size. Proper education, mindset, and access to new technologies are all crucial when making decisions. As smaller manufacturers tend to gain the most by adopting new technologies and staying competitive, they also can lose the most when investments are made into the wrong kind of technology. After all, ‘small’ firms are not the ‘large’ firms on a smaller scale. As firms get larger, their needs become more evenly distributed. According to our survey,

- ‘Improve safety, hygiene, and sanitation’ rated second at 42%,

- ‘Drive productivity and efficiency in our processes’ at 41%’,

- and ‘Lead the organization towards high performance’ at 40%.

As we attempted to seek patterns of urgency within the geographic locations and the diversified manufacturing sectors. The result – there was no significant variance. To further illustrate the strong indication that size is key, the following table is a brief illustration of the survey results by firm size:

As the nation’s second-largest concentration of manufacturers, Cook County generated a manufacturing output of $87.5 billion in 2019, accounting for over 10% of the total Illinois GDP. Manufacturers want to stay competitive, and they want to be heard! If you are interested in delving further into the topic, you may find the full report at https://www.imec.org/scc_census/.

This report is the first step towards our continuous effort to listen, understand, and strengthen manufacturing in Illinois. If you have further questions about the report, please contact us at info@imec.org.