Inventory is money. How well do you track your inventory “money”? Do you know where all of it is every day or are there piles of “money” just sitting in unknown locations? When dealing with dollars, we want to know where it is, how much we have, and be confident the amount is accurate. Remember, inventory is money. If you do not know where your inventory is, or how much you have with certainty, you are losing money.

Inventory is expensive to purchase and store but is a necessity for manufacturing. In fear of downtime, many order extra inventory “just in case”, but this only grows cost and shrinks visibility. High levels of inventory make it difficult to find what you need and identify what you do (or do not) have, all the while you pay a higher price. The solution to this “just in case” mentality is improved Inventory Management.

Proper inventory management allows you to track the inventory you have on hand, reduce the quantity of inventory sitting on your shelves, and predict when it is time to order more. With the help of some clever techniques, you can minimize your inventory costs while being confident that you have as much as you need to continue production as usual.

Assess Inventory Management: Quick Quiz

To implement the most effective improvements, it is important to understand how evolved your inventory system currently is. This can be done by assessing your company’s Inventory Management (IM) Proficiency.

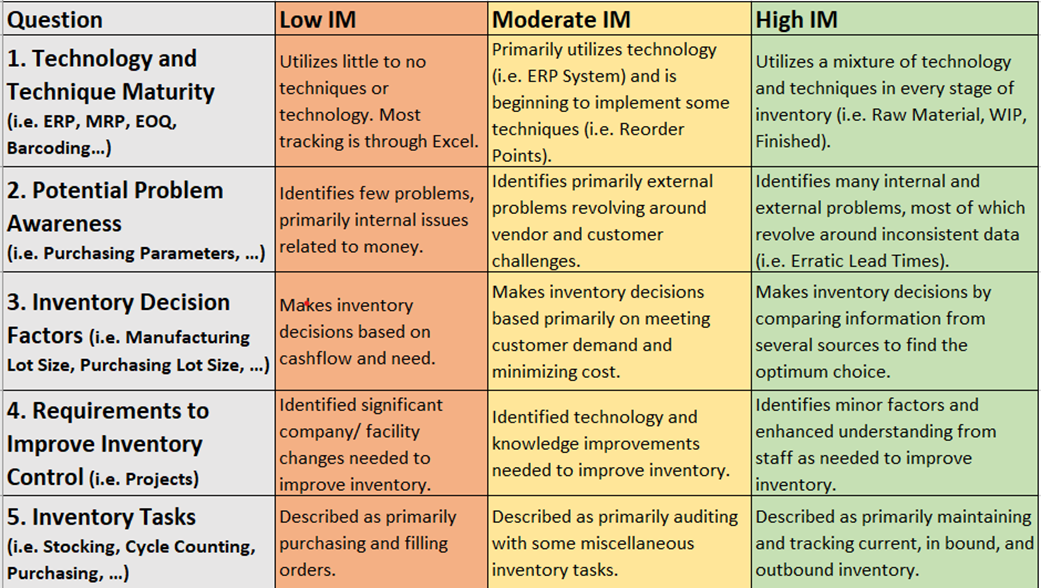

Answer these 5 questions about your company’s approach to inventory management to identify its IM Proficiency. (You may want to write down your responses for reference.) Then, in the table below, find the box that describes your response to each question. The column with the most responses is your company’s IM Proficiency.

1. What technology/techniques are used to manage inventory?

2. What factors cause inventory problems? (Internal and External)

3. What factors drive inventory purchasing decisions?

4. What needs to happen to improve inventory control?

5. What tasks do employees perform related to inventory?

High IM Proficiency Level:

Keep up the good work! To improve your inventory management, it is now a matter of fine tuning the work you have already put in. Refining reorder points, ecconomic order quantity, and auditing processes will help make your inventory as accurate and lean as it can be. Focusing on team building and 5S strategies may help to unify your inventory efforts.

Moderate IM Proficiency Level:

Keep the momentum going! To improve your inventory management, focus on learning about new technologies and techniques for inventory control. If you currently use an ERP, make sure to utilize this resource fully. If you are interested in exploring inventory management or MRO (Maintenance, Repair, and Operations) software, I encourage you to look at the IMEC Inventory Manager (more information below). Regardless of software, exploring the best ways to calculate reorder points and order quantities will be a good place to start. Looking at the flow of inventory through your parts room and facility could highlight areas where there is excess material movement.

Low IM Proficiency Level:

Remember, inventory management is a continuously improving process; every improvement you make is one more step forward. To improve your inventory management, the best place to focus energy is on the infrastructure for inventory control. This includes identifying the inventory you currently have, discarding obsolete inventory, and dedicating space to the important parts. Tracking items related to the product that is the bulk of your business will be the most impactful. Tracking this early stage will give you more information and provide insight into what else can be improved. If you are uncertain about how to start the tracking process, I encourage you to look at the IMEC Inventory Manager (more information below).

IMEC Inventory Manager: Moderate & Low IM

If your company falls in the Moderate to Low IM Proficiency categories, then this manager could benefit you. For Moderate IM, if you already use an ERP, then this could act as an alternative MRO tracking software. For Low IM, if you are uncertain how to begin tracking, this manager will prompt you to record information that is important and notify you when inventory gets low. If you track your inventory in Excel currently, this can act as a small step towards a more sophisticated inventory control software.

The IMEC Inventory Manager is a modified Excel workbook that utilizes forms to enter information. This reduces the possibility of errors and enforces continuity throughout the workbook. It can track your current inventory, orders you have placed, part usage, the last audit, and your vendors. It will also provide warnings when your inventory level reaches the calculated reorder point. This manager is also customizable to fit your company’s needs through the assistance of IMEC.

If you are struggling with inventory, know that there is a solution. Don’t let an inventory hoard pile in the corners; start your inventory management journey today. For more information about the IMEC Inventory Manager or our other services, contact us at https://www.imec.org/about-imec/contact/ .

To learn more on inventory management and talk to your regional expert, visit https://www.imec.org/about-imec/contact/.