Written by Scott Czysz, IMEC Technical Specialist

“10 Commandments of Facility Layout” has more punch, but when it comes to facility layout, very little is written in stone. Compromise is needed almost every step of the way; this does not mean there should not be a structured approach to facility layout and design. In fact, a structured approach is even more important when there is so much uncertainty and compromise.

The suggestions below are written with factory layout in mind - moving to a new facility, or rearranging your existing facility. Many of these suggestions can also apply to smaller scale department or cell layout, office layout, or even the layout of your dream home or home workshop.

1. Match your layout to your business strategy. Start with the end in mind. If you want people to collaborate, design your facility to encourage collaboration – open, common areas and windows instead of walls and dividers. On the other hand, if you need to eliminate cross-contamination of product in the factory, walls and barriers are appropriate. Think not only about what you want to accomplish in the facility, but in your organization, and then use the new layout to help achieve that.

2. Understand and comply with safety, legal regulations, and other constraints. Determine what the minimum and recommended aisle widths are for different parts of the building, and what sort of air handling and exhaust will be required for the different spaces. Find out how many exits, how many fire extinguishers, are needed; and what about the sprinkler system? Clarifying these details early on will eliminate costly changes later.

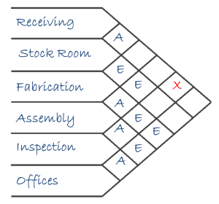

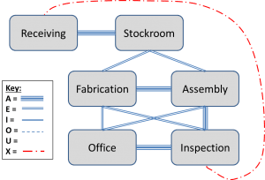

3. Understand, then optimize space relationships. Simplified Systematic Layout Planning is a time tested approach to facility layout. This approach starts with understanding and charting the relationships between all the different blocks of space in a facility – what needs to be close together, what should be close together, what should not be close together. To rank these relationships, a code of A, E, I, O, U, X is used. A means “Absolutely Essential”, E means “Especially Important”, I is “Important”, O is “Ordinary Importance”, U is “Unimportant”, and finally X is “Undesirable”, or “do NOT place close together”. Using this code and a relationship chart is the preferred approach to identifying how the blocks of space should be arranged to create the best layout.

4. Design for the future, not the present. Plan for growth and future changes. New construction is expensive. Moving equipment is expensive. Get the most from this investment by doing it right and making the new layout meet the needs now and in the future.

5. Design for flexibility and multi-use where it makes sense. If you need a large training room (or display area, or receiving staging area, etc.), but it will only be used occasionally, try to make that space multi-use. Could it also be used for meeting rooms (add portable partitions), or some other use when it is not needed for its primary use? As for flexibility, this can mean building flexibility (partitions, dividers, multi-use spaces), but it can also mean equipment flexibility. Often times, new facility layouts also mean new racking, equipment, and furniture. If so, make the most of this opportunity to obtain flexible equipment: adjustable racks, storage cabinets and workbenches mounted on wheels, etc.

6. Optimize Aisles & Services. “Aisles & Services” include all aisles, restrooms, utility rooms, and other necessary but not value-added spaces in a facility. Typically aisles & services can consume 20% or more of a facility’s total square footage. The intent isn’t to make all aisles as narrow as possible. The intent is to lay out aisles and service spaces as efficiently as possible to free up as much space as reasonable for the productive and value-adding spaces in the facility.

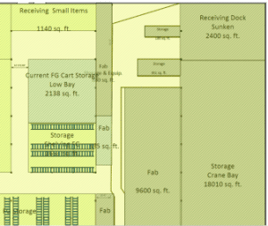

7. Use the volume of space. Creating a facility layout plan is usually done in two dimensions: on paper or a computer screen. When planning a facility layout, be sure to consider and utilize all three dimensions. Use the volume of space through the intelligent use of storage racks, other storage solutions, mezzanines, etc.

8. Flow in one direction. Whenever possible, try to have material flow in one direction. An ideal factory layout may be one that has the receiving docks on one end of the building, the shipping docks on the opposite end, and material flowing in a straight line from one to the other.

9. Maximize visibility, sight lines. Material needs to flow in the facility, and vertical space should be used. But, the material flow and the people inside the facility also need to be managed. This is more easily accomplished when the material and people within the facility are visible. Having good visibility in the facility can also be important from an employee safety perspective. Some facilities have limited the heights of equipment, partitions, and storage racks to five or six feet to allow for visibility across the facility. When thinking visibility, also think about lighting. The use of natural light through windows and/or sky lights and even light color floors can add to the light levels in a space, and can save on lighting costs.

10. Invest in designing the best layout ahead of time. It’s a lot cheaper to change a layout on the computer screen or on a sheet of paper than it is in real life. So, take the time to understand your facility layout needs and wants, then take the time to design multiple layout options, and choose the best from all those options to end up with the best facility layout for your organization.

Learn more about Scott Czysz, IMEC Technical Specialist in the field of continuous improvement, lean transformation and Six Sigma.