You shouldn’t wait until an employee is exposed to or tests positive for the COVID-19 virus. Rather, you should create a facilities plan that will help keep your employees as safe as possible.

You shouldn’t wait until an employee is exposed to or tests positive for the COVID-19 virus. Rather, you should create a facilities plan that will help keep your employees as safe as possible.

Here are some things to consider as you develop your plan:

- What kind of building ventilation do I have? Can I create more ventilation?

- Should we remove any personal and industrial fans from offices or from the shop floor?

- Can I use UV lights on any surfaces to kill bacteria?

- Do I have Safety Data Sheets for all the cleaning chemicals I am using?

- What cleaning chemicals should I use?

- Can I control personnel access in some parts of the facility?

- What are the best methods to clean surfaces in my facility?

- What surfaces should we clean and how often should we clean them?

- Who will do the cleaning?

- What PPE is needed for people doing the cleaning? How often should PPE be cleaned or disposed of?

- Have I properly trained the cleaning personnel?

- What can we do to increase distances between workers?

- What is the protocol for when an employee is exposed to or tests positive for the illness?

- How can I schedule breaks to minimize contact between employees in lunchrooms, breakrooms, and smoking areas?

- How can I alter shift hours so there is no overlap of personnel between shifts? Can we use a different communication tool for shift handoff?

- How do I create a visitor policy to ensure I am not allowing a visitor in that may create a risk to my employees?

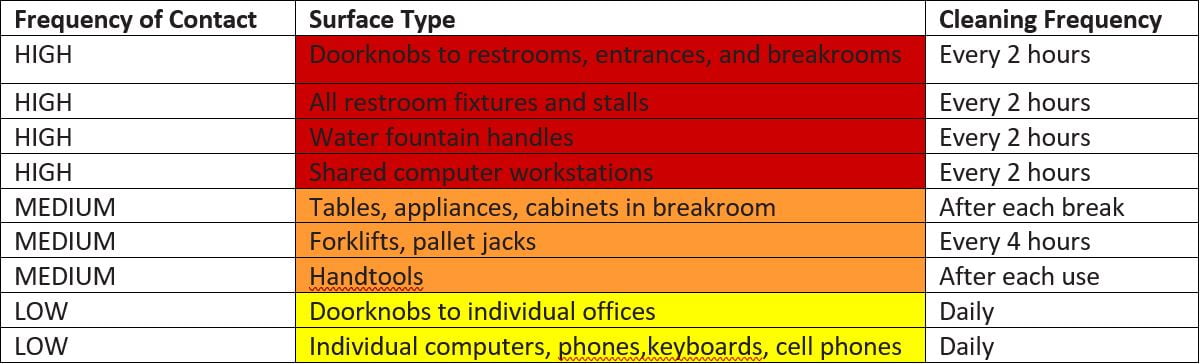

You may want to create a hazard risk assessment in order to determine the frequency of cleaning. Here is an example of how you might set one up (NOTE: this is an example and you should determine the risks for our specific facility and how often surfaces should be cleaned.)

Contact the Illinois Manufacturing Helpline with questions or concerns regarding your risk mitigation or risk management plan!