I am receiving many questions on the Illinois Manufacturing Helpline about face covering and face mask use in manufacturing facilities. Some governing bodies are requiring face coverings and not providing clear definitions or specifications on what is considered a “face covering.” Add to this the fact that manufacturers must put in place a respiratory protection program if they require fitted respiratory protection such as N95s or half face or full face respirators (take a look at OSHA regulations around respiratory protection). So, what seems simple to do becomes a multi-layered set of decisions.

Before presenting information about the different types of face coverings, it is important to understand a bit about why face masks are so important during this COVID-19 crisis. A person with the virus carries around a viral load that varies throughout the different stages of the disease. This person can shed the virus, for instance when they cough or sneeze. Then if someone else is exposed to the virus that is shed, they can be exposed to a big amount or a smaller amount and this is called the viral dose or infectious dose. It is speculated that the larger the viral dose you take in, the worse the symptoms you experience. This supposition is based on studies done for influenza, SARS and MERS. (note: I am not a physician or epidemiologist, so I encourage you conduct your own investigation. Here is an informative webinar by a physician that was recorded not too long ago).

My takeaway from the information I have been reading about the COVID-19 transmission is that even if you are exposed, the more you can minimize the dose of the exposure, the better off you are. So, that leads me to discussing some of the face covering options you can consider. Note: I am intentionally using the term “face covering” because I want to expand your knowledge beyond respiratory devices.

As a manufacturer, if you are requiring some form of PPE, in this case a face covering, then you should make an informed decision about the best type for your facility. Unfortunately, beyond N95 masks or other fitted respiratory devices there has been little information available to help you make an informed decision. The good news is that Northeastern University recently published a study they conducted to determine the efficacy of different face coverings. This study, updated as recently as April 17, 2020, has not yet been published; however, the researchers have made it publicly available. I encourage you to read the study for yourself to understand their testing methods and determine your own confidence in the data. I do want to highlight some of their findings:

- The material the mask is made from plays a significant role in the efficacy of the mask

- You can increase the tightness of the fit of the cloth masks by using a nylon stocking

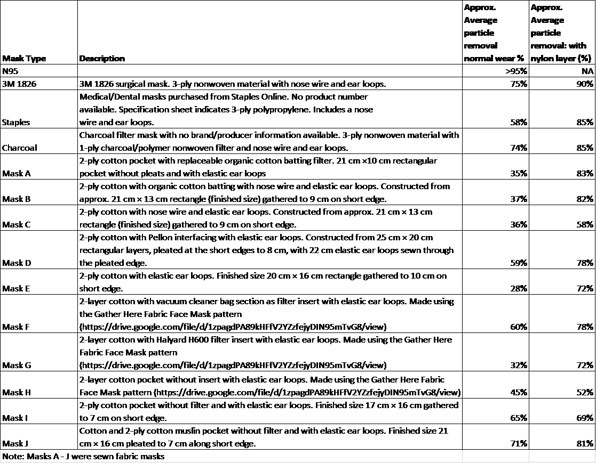

I created a table below based on what I read in Figure 5 of the report. The highlight of the findings are how closely a cloth mask can get to blocking particles when used along with a nylon band. Please note that these are approximate values based on my interpretation.

Actions for you to take as you consider face coverings for your employees:

- If you require N95 masks, be aware that they fall under the OSHA requirements for a respiratory protection program. As for now, the fit testing requirement has been relaxed in all industries. You should still make your best effort to help employees maintain a good fit if you require these respiratory devices.

- If you require a surgical mask or cloth face covering, select a mask with a tightly woven fabric, consider whether to use one with some sort of liner or filter between layers, and determine whether you want to encourage the nylon stocking band to increase effectiveness.

- Make sure employees cover both their mouth and their nose with the face covering. This can lead to glasses and safety glasses fogging, so make sure you have anti fog wipes available or help employees adjust the masks to avoid their glasses fogging. They must be able to see in order to work safely.

- Provide training on how to handle the masks when removing them. It is generally better to remove them by the straps so that a person doesn’t touch the front of the mask that may have been exposed to the virus.

- Determine how you will handle used masks – Will you throw them all away? Will you collect them to get them laundered? When should they be placed in trash or laundry – at end of day, each time you remove them? Make sure employees don’t leave them lying around where they could contaminate other surfaces.

You should treat even a face covering as you would any other PPE that you require your employees to use. Make sure it is the correct design, train employees how to use it, and inform them how to clean or dispose of it properly.

Have a question of your own? Ask an expert on the Illinois Manufacturing Helpline and get a quick response.