IMEC and our partners are ready to serve you! The experts at IMEC have packaged the tools and resources you will need to survive current disruptions, while strengthening your business continuity plan:

Recent Posts

COVID-19 Pandemic: Manufacturers’ Greatest Time of Need

Posted by Simone Erskine on Mar 27, 2020 3:19:00 PM

Meet StratMarketing Group, the Relationship Builders for Illinois Manufacturers

Posted by Simone Erskine on Feb 25, 2020 8:03:00 AM

Who is StratMarketing Group?

StratMarketing Group (StratMg) is a demand generation company that places high value on building authentic relationships with customers and partners.

Prior to starting StratMg, Parin Mody contributed to deploying one of the first implementations of Voice-over Internet Protocol (VoIP) in the United States. From there, he transitioned into product marketing within manufacturing that eventually led to marketing and sales experience specifically within the manufacturing industry in the United States - hence, StratMg was formed.

Addressing the Workforce Challenge: Inspirations from the 2020 Conference on Enterprise Excellence

Posted by Simone Erskine on Feb 5, 2020 9:22:33 AM

What does it take to build a truly remarkable team and a high performing organization? At the IMEC 2020 Conference on Enterprise Excellence, leaders in manufacturing, healthcare, education and business will come together to highlight best practices and strategies they use to achieve performance excellence. Despite representing different industries, these organizations have taken a similar path to performance excellence, and as such have overcome common challenges across industry. One challenge that is all too familiar to manufacturers is the workforce crisis. With the rise of the silver tsunami, manufacturers – and other industries – must take strategic actions to protect and build their greatest asset – their people.

Kane County Partners with IMEC to Ignite Manufacturing Innovation and Productivity in Kane County

Posted by Simone Erskine on Jan 30, 2020 2:22:04 PM

Manufacturers across the state are taking advantage of IMEC’s Illinois Manufacturing Innovation Voucher program! Just last November, IMEC announced a leading-edge economic development program to help small and medium-sized manufacturers accelerate technology adoption in their products and processes. Awarding up to $25,000 in matching funds, Illinois manufacturers can obtain external technical assistance to solve technology adoption challenges.

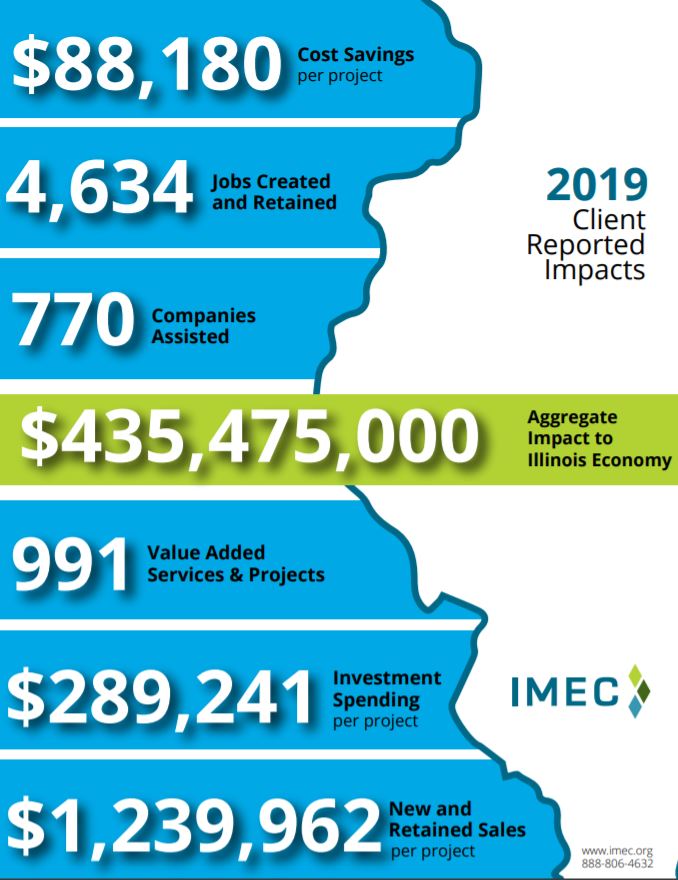

770 Companies Report Impacts that are Improving Illinois Manufacturing

Posted by Simone Erskine on Jan 17, 2020 9:47:38 AM

As the cliché, but true saying goes: “numbers don’t lie.” We can’t help but agree as we review our 2019 client reported impacts! While it is certainly a time of celebration here at IMEC, it’s also a celebration for the 770 manufacturers who have invested in their competitive futures. By partnering with IMEC and reporting the impacts our work has contributed to their business, it allows us to show that we all play an important role in a much bigger story. These numbers speak volumes to the value our clients add to our manufacturing ecosystem. Not only are companies on a path to enterprise excellence, but they are also strengthening Illinois’ economic well-being, their communities, and their organization as whole.

2020 Conference on Enterprise Excellence: Learning from High-Performing Organizations Across Industries

Posted by Simone Erskine on Jan 6, 2020 2:36:21 PM

Every year, IMEC hosts the Conference on Enterprise Excellence. During this one day of incredible learning, manufacturers, healthcare professionals, educators, and business leaders come together to share best practices in performance excellence that can be applied to any operation.

You may be wondering: “what can a manufacturer learn from a hospital or a school?” Well, a lot. Every organization has similar areas of focus – leadership, workforce, strategy, operations, customers, measurement and results, and technology implementation. Ensuring that these areas are held to high standards will result in a high performing organization. The 2020 conference features business leaders who have transformed their organizations into reputable, high performing ones by implementing trusted and effective strategies that are replicable for any industry.

Team Spotlight: Mary Hallock

Posted by Simone Erskine on Dec 11, 2019 10:55:39 AM

Mary is an IMEC Technical Specialist who helps manufacturers improve their business and leadership strategies. She has been with the organization for 14 years and has over 22 years of experience in the chemical and food ingredient industries. Since her time with IMEC, Mary has helped Illinois manufacturers grow and maintain over 300 jobs and generate an aggregate impact of over $27M.

Made in Illinois Featured Company: Termico Technologies

Posted by Simone Erskine on Dec 6, 2019 12:55:26 PM

Termico’s core competency is the engineering, manufacture, and testing of self-regulating, PTC heaters. At Termico they strive to offer best-in-class application engineering support to assist customer product development efforts. With 80+ years of PTC industry knowledge on staff, they understand what it takes to produce safe, stable, and reliable heaters.

Igniting the Future of Illinois Manufacturing: The Illinois Manufacturing Innovation Voucher

Posted by Simone Erskine on Dec 3, 2019 1:48:38 PM

Imagine the strides your company will make as keep pace with manufacturing technology.

Exciting things are in store for Illinois’ small and mid-sized manufacturers (SMMs) in the coming year! If you haven’t heard already, IMEC recently announced the revolutionary Illinois Manufacturing Innovation Voucher program for SMMs to invest in R&D and technology adoption.

SMMs are vital to the economic well-being of Illinois, and to continue a thriving manufacturing industry in the state, the Illinois Manufacturing Innovation Voucher will lead to a total of $2.5 million in investments to assist with approximately 50 projects in the next year.

LMI Chicago: Taking Leaders to the Next Level

Posted by Simone Erskine on Oct 3, 2019 12:12:43 PM

Who is LMI Chicago?

LMI Chicago is part of a worldwide organization called Leadership Management International. For over 50 years, in 80 countries and 27 languages, LMI programs have helped develop effective and productive leaders. Jeff Johnson, President of LMI Chicago, personally completed the LMI programs with his management team (at his previous company) prior to starting LMIChicago four years ago. Witnessing the benefits, Johnson was attracted to the proven programs and processes and the difference they made in people’s lives.